USES AND APPLICATIONS

Brick factories.

Placing of exposed work.

Block placement.

Floor support (cementitious adhesive support layer).

And all kinds of masonry work in general, carried out indoors or outside protected.

PREPARATION

The mortar type M-7,5 Silícico packed in bags is prepared in a concrete mixer. Add 4.0 liters of water for each bag of mortar (0.16 liters / kg). Depending on the application, it can be up to 4.5 liters (0.18 liters / kg of mortar)

|

HOW TO USE

The support must be clean and damp. Do not apply to paint, plaster or dissolvable surfaces.

Spread the paste on the support or piece with the help of a trowel or trowel depending on the application.

For masonry works, a soft consistency between 170 and 180 mm of runoff is recommended.

For plastering or rendering, it is recommended to give it a fluid consistency, drainage > 190 mm.

The mortar use time in optimal conditions is 90 minutes, depending on the weather.

It is recommended not to use them when it is expected that the temperatures in the setting process could exceed 40 °C or the temperature could drop below 4 °C.

STORAGE

Covered and dry rooms, avoid humidity environmental areas.

Properly stored material can be used for up to one year from the date of manufacture.

|

SAFETY

This product contains cement.

Avoid contact with eyes and skin, as well as inhalation of dust.

Wear protective gloves and goggles.

Keep out of the reach of children.

FEATURES

Cement: Type I / 42.5 R.

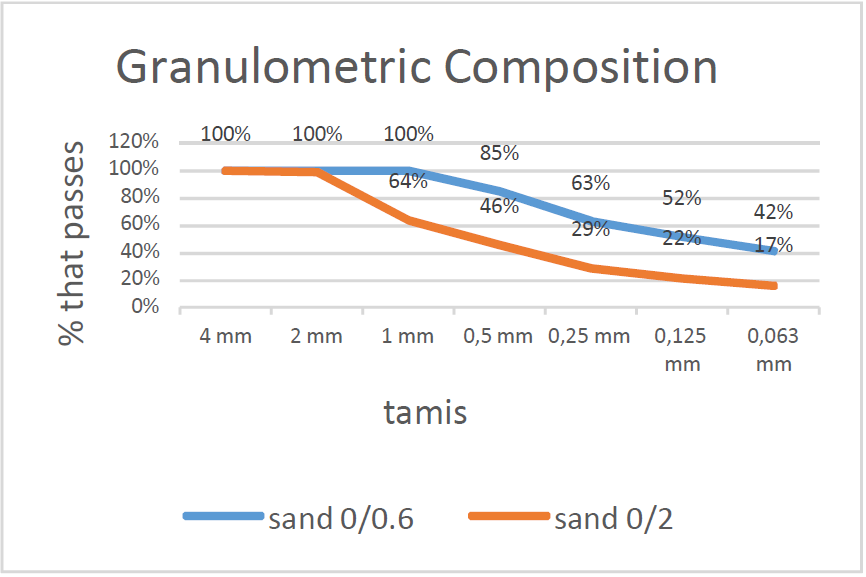

Arenas: Arena 0/2 mm.

Arena: 0/0.6 mm Silicics.

Additives: Inorganic.

|

RESISTANCES

Compressive strength following the indications of the UNE EN 1015-11 test standard at 28 days is 7.5 N / mm2.

Note: The recommended water for a 175 mm drainage according to UNE EN 1.015-3, is 0.125 liters per kg of mortar.

QUALITY

The mortar type M-7.5 is manufactured according to the UNE EN 998-2: 2016 standard (mortars for Masonry) complying with all the parameters indicated in annex Z1 of said standard. The test standards used to control mortars manufactured are the following:

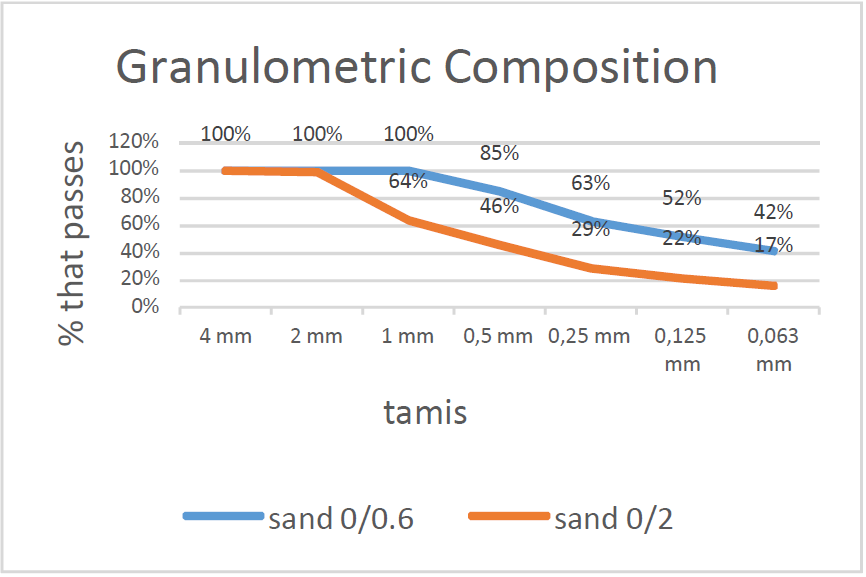

UNE EN 1015 -1 "Granulometric Composition"

UNE EN 1015 -2 "Collection of mortar samples"

UNE EN 1015 -3 "Value of runoff by shaking table"

UNE EN 1015 -11 "Compression resistance value of mortars"

The data provided is based on tests carried out in our control laboratory and contrasted with laboratories accredited by the Generalitat de Catalunya.

|